Weld from start to finish…

We wanted to introduce you to weld, one of the workhorse plants of the dye garden and one we recently finished taking through a full cycle of planting, growing, harvesting, and using in the dye pots.

Weld (Reseda luteola):

Also known as dyer’s rocket or dyer’s weed, this biennial native of Europe and Western Asia has been used since at least 1,000 BC to color textiles a clear, bright, sunshiney yellow. It can be a bit invasive (it has thousands of tiny black seeds in every plant!) so is best grown in designated beds, like we did last year in our dye garden. Some historians suggest that weld was overdyed with blue from woad to make the green color of Robin Hood’s garments!

The main (but not only) dye compound in weld is luteolin, which is also present in goldenrod. We do forage goldenrod and also use it in our natural dye processes, but it has to be frozen rather than dried to retain the best color, so it is more energy- and space-intensive than weld.

Weld grows 5-6 feet tall in its second year and sends up long greenish-yellow spikes with many small flowers. We harvested our weld in June by chopping it off at the base and then hanging the long stalks upside down in the garage with a sheet underneath to catch the tiny seeds.

In November we took the dried weld down and shredded it—stem, leaves, flower spikes and all—in a chopper designed for sticks and brush. We found this worked great and didn’t produce too much dust if we put a large cooler underneath to catch it all. Some pieces were a little large and had to go through a second time, but it really was all done amazingly fast—less than 20 minutes for all of our large bundles. If you want to see this process in action be sure to check our our video on our YouTube channel.

A cooler full of dried, chopped weld plants

In December we got to actually dye with our own weld for the first time—previously we had used some weld we got from our friend and natural dyer Jean Haley or had used weld extract we purchased from Maiwa. Although it takes an extra step to simmer the weld for an hour or so to extract the color, rather than just mix the extract in hot water, there’s nothing like the smell of weld and the knowledge that you sustainably grew and harvested your own color right outside the back door of the studio.

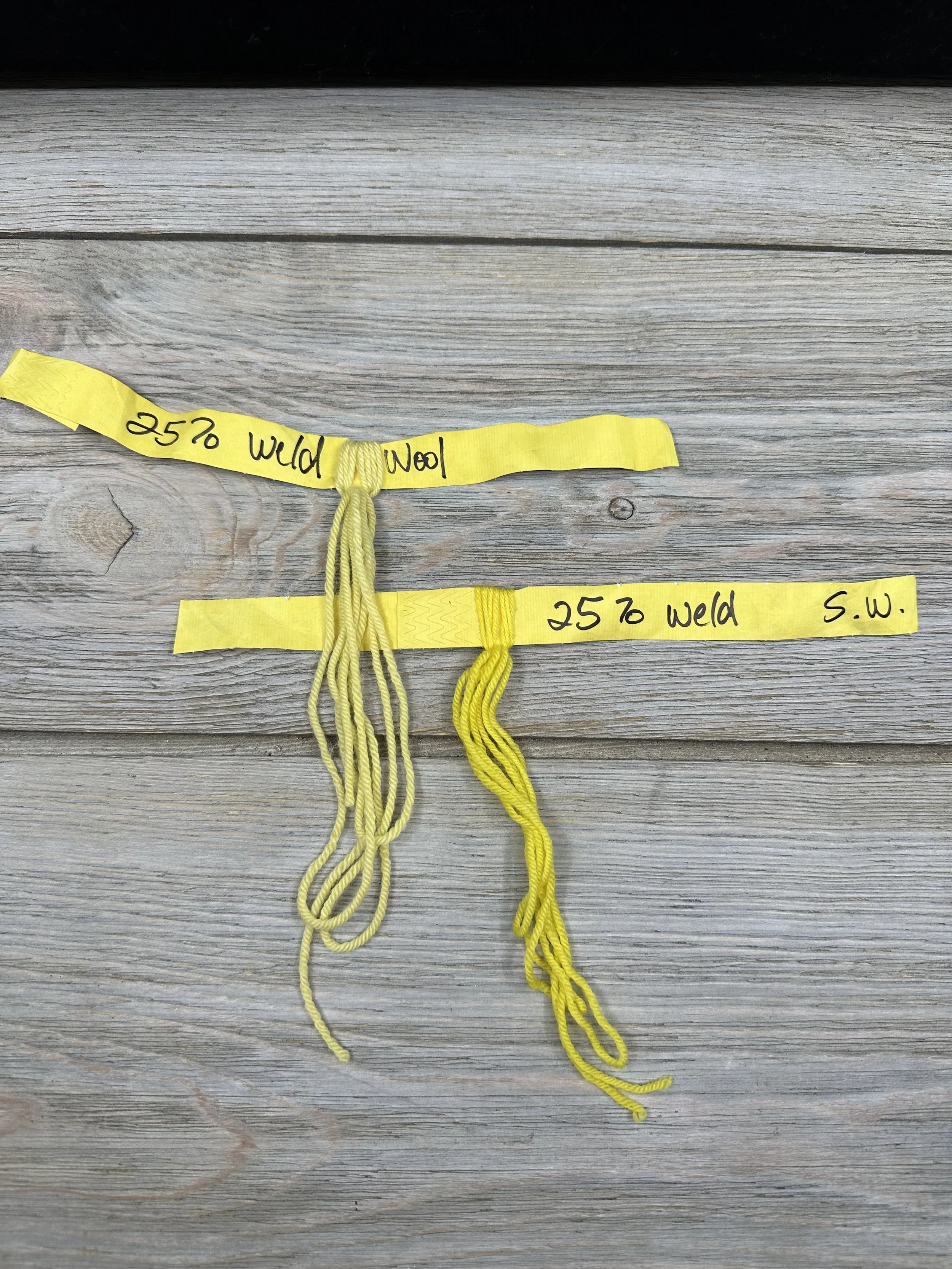

Weld sample dyes

Both of these test skeins used 25% weight-of-fiber weld ; the one on the left is on pure (non-superwash) wool, and the one on the right is on superwash merino-cashmere-nylon. The superwash tends to take natural dyes more intensely than natural wool does.

“Lily Pond” on Merino/Cashmere/Nylon

We’re very happy with the strong, clear yellows our weld crop is giving, and plan to use it as much as we can in the year ahead to make some of our signature colors like Moss, Blue Spruce, Lily Pond, and Monet’s Garden. We love the combination of weld and copper to give bright mossy greens. We also like to use exhaust baths of weld to prepare yarn pre-mordanted with alum for overdyeing with indigo to get the clear grassy greens we love so much. Some dye sources say that the strongest yellows are given with fresh, not dried plant material, so maybe next season we will try that and compare the results.

Rosettes of weld growing in our raised bed dye garden

We planted another batch of weld seeds in August to get the first “year” of growth in the latter half of the summer so it will shoot up and set seed next spring. This is technique that can work with biennial plants so you will have a crop to harvest each year. Those rosettes grew well, so we are hoping for another good harvest this coming June.

Weld seeds!

Tiny weld seeds and chaff we gathered from the sheet underneath where the weld was hanging. We poured the seeds and chaff from the sheet into our hands and gently blew across it to scatter the chaff.

It seems that the process of growing, harvesting, and dyeing with our own weld was pretty straightforward so we plan to keep it up—we will see how far our crop takes us in our dyeing, and may need to make another bed to grow some more since we do use it quite a lot in various shades of green and blue. We do have lots of seeds, so let us know if you’d like to try growing your own. And if you want to see this process of growing, harvesting, and using weld in action, head over to our ColorMeHappy YouTube channel and check out our full length Weld video!